#LOCK OUT TAG OUT VIDEO HOW TO#

Once you have completed your checkout, you will receive an email with simple instructions on how to watch and access your video. Get instant access to the highest quality safety videos through Video on Demand (VOD) in the media options. This safety video program is produced by The MARCOM Group, Ltd. 1910.147 - The Control of Hazardous Energy (Lockout/Tagout).1910 Subpart J - General Environmental Controls.The safety video program comes with a quiz, a scheduling and attendance form, a training certificate, and an employee training log.

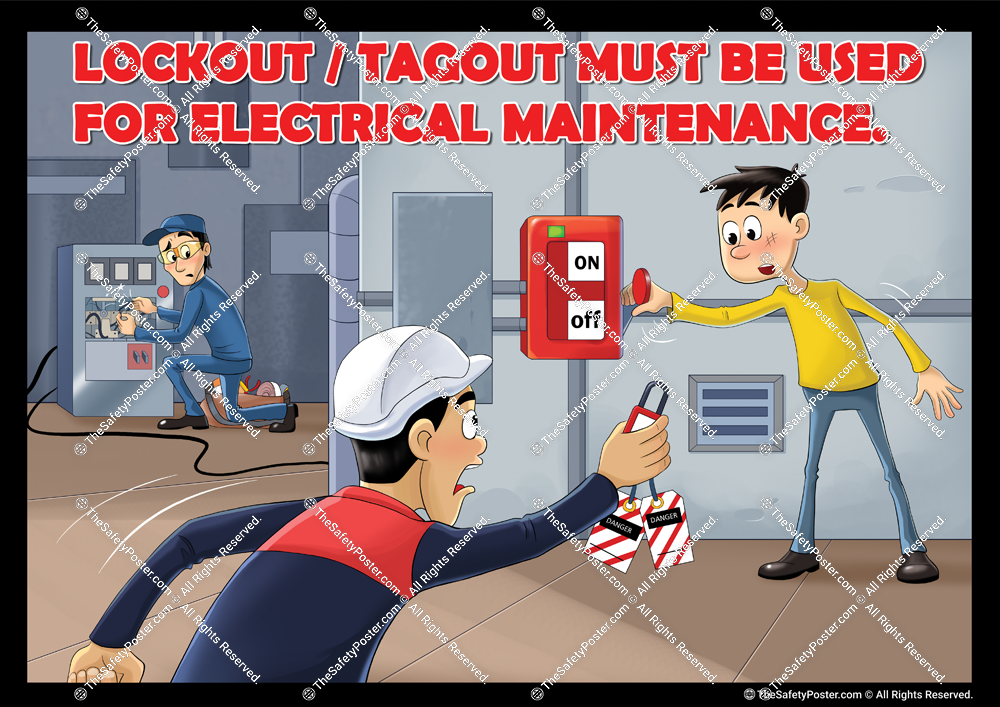

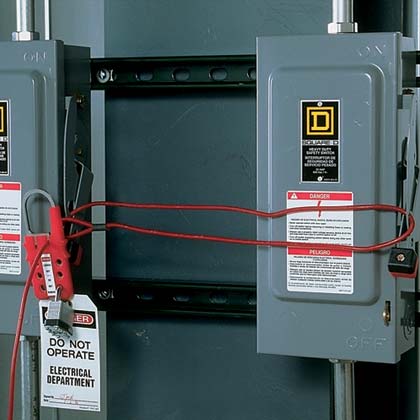

The process of tagging out a system involves attaching or using an information tag or indicator (usually a standardized label) that includes the following information: Why the lockout/tag out is required (repair, maintenance, etc.).

This week's video introduces the concept a little further, and explains how vital it is to worker safety. Tag out is a labelling process that is always used when lockout is required. This practice helps ensure that moving parts don't move when you're working on them (unless you want them to), and that no electricity is flowing through equipment that can shock you while you're repairing it. One important maintenance safety practice is known as lockout/tagout, or what OSHA now calls the Control of Hazardous Energy. Whatever the reason, the important thing to remember is to be safe, no matter what life is throwing at you while you're out getting your hands dirty. Probably it's just that those are the breakdowns we find more memorable, while the quick fixes on sunny spring mornings fade into the background. 1.Identify all energy sources which need to be disabled to create a safe working environment such as electrical, pneumatic, hydraulic, gravity, nuclear. Train your employees to protect themselves from hazardous energy. Why do things never seem to break when the weather's nice out? Somehow, whether it's the roof over your house, the battery in your car, or the machinery at your utility, things always seem to have a way of breaking down right when it's pouring rain, or there's a raging blizzard, or the temperature's over 100. Length: 1:56 Author: US Department of Labor Lockout Tagout Training XO Safety has great training options for Lockout Tagout.

0 kommentar(er)

0 kommentar(er)